Specifications are subject to change without prior notice.

GCC Laser Cutter - T500

Categories: Workshop Equipment , CNC & GCC Laser Solutions , Laser Cutters , Workshop Equipment , CNC & Laser Solutions , Laser Cutters & Engravers

Equipped powerful 200W laser allow user to deliver clear and fine cutting result. GCC LaserPro T500 Laser Cutter is capable of exceptional 3D engraving quality and cutting at high speed which make it a high ROI laser system on the market.

Top Key Features

- RoHS Compliance

- AC Servo Motor and Unique Motion

- Excellent Speedy Scribing Quality

- AAS Contour Cutting Device (patented)(Optional)

- SmartPOINT Positioning Device (Patented)

- Outstanding Cutting Capability

Overview

Equipped powerful 200W laser allow user to deliver clear and fine cutting result. GCC LaserPro T500 Laser Cutter is capable of exceptional 3D engraving quality and cutting at high speed which make it a high ROI laser system on the market.

The T500 is a dedicated design to fulfill your cutting and engraving needs in one machine with high throughput and superb quality. With a series of user-definable features, the T500 is the flexible and user-friendly laser system for your choice.

Key Features

- RoHS Compliance

- AC Servo Motor and Unique Motion

- Excellent Speedy Scribing Quality

- AAS Contour Cutting Device (patented)(Optional)

- SmartPOINT Positioning Device (Patented

- Outstanding Cutting Capability

- Superior Engraving Quality

- Knife-shaped Cutting Table

- LED Light Illumination System

- Grid Cutting Table

- Pass-through Front to Rear Doors (Optional)

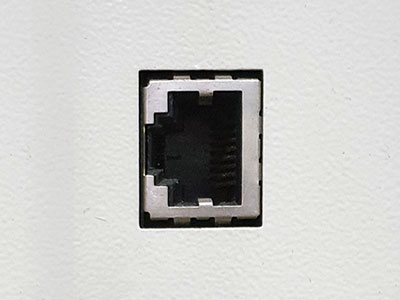

- Built-In Networking Connection

- Bridge Cutting

Dimensions

| Dimensions: | 1900 x 1400 x 1200 mm |

|---|---|

| Weight (Gross): | 420kg /440 kg |

| Work Area: | 1300 x 905 mm |

Max Part Size (L x W x H)

| w/o Cutting Table | 1346 x 916 x 127 mm (2"/4" lens ) |

| 1346 x 916 x 76.2 mm (6" lens) | ||

| All Doors Open | 1346 x ∞ x 25 mm (2"/4" lens) | |

| With Cutting Table | 1325 x 889 x 114 mm (2"/4" lens) | |

| 1325 x 889 x 38 mm (6" lens) |

Technical Specifications

| Computer Interface / Network: | 10 Base-T Ethernet USB Type-A 2.0 – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0 – For connecting with the computer |

|---|---|

| Display: | 4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. |

| Electrical: | 200-240VAC. 50/60Hz auto switching, Max.15A 200-240VAC. 50/60Hz auto switching, Max. 25A 200-240VAC. 50/60Hz auto switching, Max. 30A |

| Extraction System: | External exhaust system with minimum flow rate 2000m3/h (CFM 1177 ft3/min) is required, 3.8kPA negative pressure (Pure-Air PA-2000FS-IQ @ 8" exhaust port) |

| Safety: | Class 1 Laser Product Compliant with EN60825 Class 2 Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

| Speed: | Max Speed*: 1.01 m/s (40 in/s) |

| Build Plate: | Cutting Table Knife-shaped cutting barswith alumminum grid cutting table |

| Cooling: | Air-cooled / Water-cooled |

| Distance: | Distance Accuracy: 0.254 mm or 0.1% of move, whichever is greater |

| Drive: | AC servo Control |

| Engraving Capability: | 256-level gray scale image processing capability |

| Focus Lens: | Standard 4" focal lens in enclosed lens carriage (Optional 2"/6" lens ) / Standard 6" focal lens in enclosed lens carriage (Optional 2"/4" lens ) |

| Laser Source: | Sealed CO2 Laser |

| Laser Wattage: | 60 W / 80 W / 100W / 150 W / 200 W |

| Power Control: | Adjustable from 0-100% (Up to 16 color-linked power settings per job) |

| Resolution / DPI: | Available125, 250, 300, 380, 500, 600,760,1000, 1500 |

| Speed Control: | Adjustable from 0.1-100% (Up to 16 color-linked speed settings per job) |

| Z-Axis: | Manual |

*Speed does not equal to throughput.

*The flow rate is determined by a default fume extraction system; the flow rate may vary due to a different fume extraction system.

Optional Items

Wi-fi Router

Wi-Fi router allows you to transmit data through a wireless network. It can work with GCC laser engravers and RX II/ Jaguar V cutting plotters through the Ethernet port (not applicable for Japanese users.) Whether you are sending files to multiple GCC machines using one PC or sharing one unit of GCC machines with multiple PCs, this wireless technology can be an excellent helper

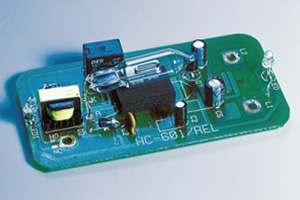

Stack Light Set

The indicator will flash to signal the end of job process and is ideal for working environment where audibility is weak.

Red light stands for “Error”; Green light stands for “ Stand-by”; Yellow light stands for “Machine is working / Insert the pass-through door key”

(This item is available for machine with 5272 V3 Mainboard and afterwards)

Red light stands for “Error”; Green light stands for “ Stand-by”; Yellow light stands for “Machine is working / Insert the pass-through door key”

(This item is available for machine with 5272 V3 Mainboard and afterwards)

SmartGUARD™ Fire Alarm (Patented)

Laser engraving and cutting operation using the SmartGUARD Fire Alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut-down the operation system immediately.

Rotary Chuck

The rotary chuck for GCC LaserPro Spirit series and S400 is a handy tool used for laser engraving on cylindrical or spherical objects. In addition to the standard X, Y, Z axis, the rotary chuck allows for the fourth axis which rotates the object 360° to allow for engraving on cups, wine glasses, and even spherical objects. Supports diameters from 0.5–120 mm, lengths up to 410 mm, and weights up to 4 kg.

SmartPRINT™

SmartPRINT™ software features powerful functions, an intuitive interface, and built-in GCC LaserPro laser parameter setting for both Mac and Windows users. SmartPRINT™ provides clipart libraries, compatibility for various file formats, and advanced graphic functions such as Auto Trace Image Contour, Convert to Rhinestone, Generate Puzzle, and many more. Also, the additional text justification and sizing options can convert stroke to the path.

Supporting Pin Kit

This design can firmly hold up the working object preventing it from falling off; moreover, it can effectively reduce the possibility of the reflected laser hitting the working object.

Air Extraction System - T500, X500III

To accomplish strong vacuum ventilation requirement for industrial application, GCC LaserPro X500III and T500 are recommended to supply a more powerful air extraction unit with 8” opening to reach the optimum cutting quality. The air extraction system powered by a maintenance-free turbine takes out the fume and dust generated during laser processing efficiently and effectively, leaves a quality cutting edge and clean operation environment.

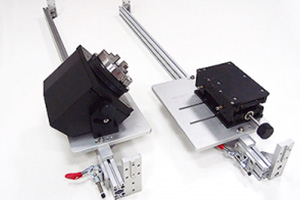

Rotary Chuck - T500

A separate design rotary chuck is special for T500 to work with cylindrical metal objects like pipes, engineering parts, and even spherical objects with the tilt angle. The rotary chuck can work with a 4" or 6" focus lens. The diameter range of the to-be-engraved object is 0.5mm to 120(4" lens) / 80(6" lens) mm and the max. length of the object is 900mm for 4” lens and 840 mm for 6” lens. Its maximum weight should not exceed 4kgs.

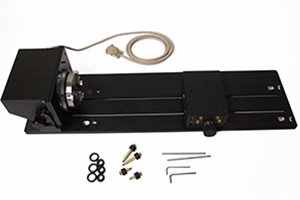

Roll Holder System

The optional Roll Holder System for users to manually load roll media like flex, films, labels, technical fiber, felt and more materials for laser cutting and engraving jobs.

Extension Table

Extension Roller Tables help loading and unloading large piece work piece with ease, furthermore, it extends the maximum parts size to work with T500. T500 standard work area is 1300x905mm (51”x35”), and it will extend by 1300x600mm (51”x23.6”) respectively in front and rear side of machine when adding extension tables. Therefore, the maximum work piece you can load will be 1300x1500mm (51”x59”) in total.

Design with mechanical hard stop to ensure the origin position and clamping fixture to hold work piece

Design with mechanical hard stop to ensure the origin position and clamping fixture to hold work piece

Water Chiller

The water chiller that will be connected to the machine consists of a cooling system, and two tubes that allow inflow and outflow of water. When you turn the power on, the cooling system is activated and delivers cool water to the laser module to absorb heat produced there, and then brings it back to the cooling system to cool down.

SmartAIR™ Fine Nozzle

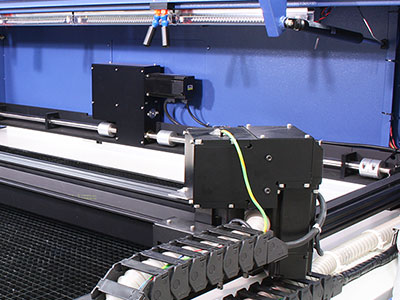

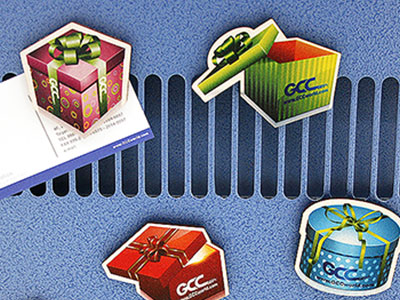

Developed by GCC LaserPro, AAS is an exceptionally user-friendly operation which offers accurate and faultless contour cutting by automatically tracking the position of graphics for laser engravers and cutters.

Note: Working area and engraving speed will be reduced when AAS module is installed.

Note: Working area and engraving speed will be reduced when AAS module is installed.

SmartTOOL™

The GCC SmartTOOL™ is a Windows CorelDraw extension that drastically reduces process times. It simplifies tasks, saves time, and is intuitive to use without training. You will be amazed by its features.

Spirit LS PRO Laser Engraving Features

RoHS Compliance

All GCC products are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide environmentally friendly products to protect the earth for our further generation.

AC Servo Motor and Unique Motion

High toque and high speed AC servo motor assures long motor lifetime and high precision. A light weight and high strength structure together with AC servo motor and steel cord belt to provide first class stability and accuracy.

Excellent Speedy Scribing Quality

T-500 embrace extraordinary control system and rigid motion system allow user to create top-notch vector scribing quality with high speed.

AAS Contour Cutting Device (patented)(Optional)

Developed by LaserPro, AAS is an exceptionally user-friendly operation which offers accurate and faultless contour cutting by automatically tracking the position of graphics.

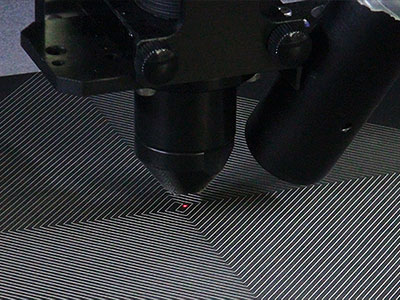

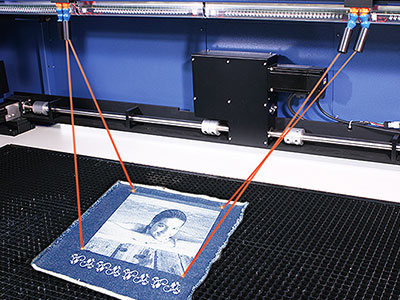

SmartPOINT Positioning Device (Patented)

Material positioning made extremely easy by use of 4 red beam diodes. Simply aim each red beam diodes at distinct points on the material and the red beam becomes a very useful positioning tool to replicate previous jobs precisely.

Outstanding Cutting Capability

T500 delivers high cutting quality with LaserPro's unique laser firing control technology. Up to 200W output power options, GCC LaserPro T500 can cut through 1" (25 mm) acrylic in a single pass with a smooth finish and unmatched clear cutting edge.

Superior Engraving Quality

T500 persists with GCC LaserPro's excellent engraving capability. Having cutting and engraving capability in one product, no more time wasted on switching materials from cutting and engraving machine. Compare to conventional cutting product. It is difficult to have a good and consistent raster performance with large working area, but T500 can.

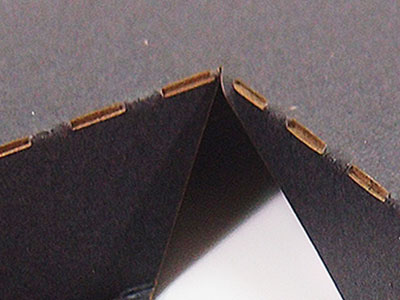

Knife-shaped Cutting Table

Unique cutting table with tipped bars that can be easily adjusted without tools to create different levels of working depths. The cutting table of T500 reduces laser reflections and delivers clear cutting edge.

LED Light Illumination System

A LED light module that illuminates the working space and makes every engraving detail easy to see.

Bridge Cutting

Bridge Cutting function diversifies the laser cutting into packaging prototyping and fulfill versatile requirements. Define the cutting gap to create the dashed line effect from user friendly print driver interface.

Pass-through Front to Rear Doors (Optional)

A design with doors on both ends to accommodate extremely long working pieces, front door without the need for a screwdriver.

Built-In Networking Connection

Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using network connection. Free your designers with great flexibility and maximum machine versatility

Grid Cutting Table

The grid cutting table is an ideal pal for laser cutting. It lifts the work piece off the work table from hitting by laser reflection while supports it with reinforced grid design. The dust and vapor created during laser cutting are then taken away effectively through the grid by down vacuum exhaust (suggested using SmartBOX™ together). Rather than handling rigid materials, grid cutting table also helps to fix flexible materials with the aid of down vacuum SmartBOX™ to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.

GCC LaserPro - T500 Introduction Video

GCC LaserPro T500 is capable of exceptional 3D engraving quality and cutting

Developed on the basis of GCC LaserPro’s accumulated technology with new powerful motion system. GCC LaserPro T500 is capable of exceptional 3D engraving quality and cutting at high speed which make it a high ROI laser system on the market. Equipped powerful 200W laser tube allow user to deliver clear and fine cutting result. GCC LaserPro T500 is a dedicated design to fulfill your cutting and engraving needs in one machine with high throughput and superb quality. With a series of user-definable features, the T500 is the flexible and user-friendly laser system for your choice.

LaserPro Products overview & specs

GCC LaserPro Laser Engraving and Cutting Machines│Product Overview & Specification - 2025

GCC LaserPro - Products Overview & Specification