Flamefast Gas Fired Kiln - LN1000

A popular small multipurpose semi-muffled gas fired kiln for both the professional and student user. The Flamefast LN1000 provides controlled heat up to a maximum temperature of approximately 1000°C.

Top Key Features

- Simplet to install and maintain

- Versatile multi-purpose unit

- Piezo Spark Ignition eliminates lighting problems

- Flame Failure Device means if there is no flame, there is no gas

- Heat Control Valve ensures simple, safe temperature control

- UK Manufactured

Overview

A popular semi-muffled gas fired kiln for both the professional and student user. The LN1000 provides controlled heat up to a maximum temperature of approximately 1000°C. The LN1000 Gas Fired Kiln has many uses including metal heat treatment, enamelling, melting precious metals and wax burn-outs. It is used by students of jewellery, dental and laboratory technicians. The unit reaches 850°C in just 15 minutes and can reach approximately 1000°C in 35 minutes.

The LN1000 is designed for use with natural gas or low pressure bottled gas, the LN1000 can be permanently installed. The constant heat input combined with spaceage insulation produces a stable operating temperature with minimum gas usage. Requires 240V.

Key Features

- Piezo Spark Ignition eliminates lighting problems

- Flame Failure Device (no flame = no gas)

- Heat Control Valve ensures simple, safe temp control

- Unique Safety Door provides minimum heat exposure

- Temperature Indicator / display

- Efficient in use (min gas usage)

- High grade insulation

- Constant heat input

- Controlled heat up to 1000°C

- Versatile, multi-purpose unit

- Simple to install and maintain

- Fast system - 850°C in 15min

- Natural or low pressure bottle gas can be used

- 2 year warranty

- UK Manufactured

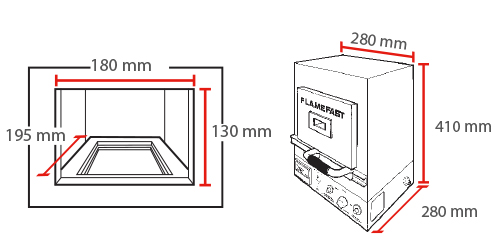

Dimensions

| Width: | 280 mm |

|---|---|

| Height: | 410 mm |

| Depth: | 280 mm |

| Internal Length: | 195 mm (Internal Depth) |

| Internal Width: | 130 mm |

| Internal Height: | 130 mm |

| Weight: | 11.8 kg |

Technical Specifications

| Electrical: | 240V AC (for temperature display) |

|---|---|

| Safety: | Appropriate PPE must be warn at all times when operating equipment Heat control valve Flame failure device (no flame means no gas) Safety door |

| Temperature: | 1000°C - Max |

| Warranty: | 2 Years |

PLEASE STATE GAS TYPE WHEN ORDERING

IMPORTANT NOTICE: ACCORDING TO THE HEALTH & SAFETY AT WORK ACT 1974, BS 4163 AND COSHH REGULATIONS IT IS MANDATORY THAT ALL FUMES MUST BE REMOVED AT SOURCE.

Performance

| Gas Type | Rate | BTU / HRS | kW | Pressure |

| Natural gas | 0.3 m3/h | 11 000 | 3.22 | 20 mbar |

| Propane | 0.23 kg/h | 5 000 | 3.22 | 35 mbar |

| Butane | 0.23 kg/h | 5 000 | 3.22 | 28 mbar |

Applications

- Enamelling

- Metal Heat Treatment

- Wax Burnouts

- Melting Precious Metals

- Laboratory Use

- Dental Work