Specifications are subject to change without prior notice.

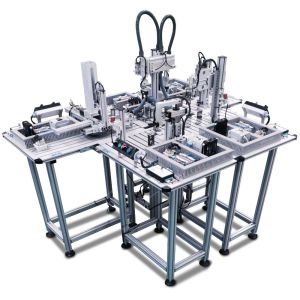

FAS-200 - Flexible assembly system

Categories: T Levels & Engineering , T Levels & Engineering , SMC Technology Trainers , Mechatronics , SMC Training Systems

FAS-200 is a flexible and compact assembly system which includes industrial automation technologies. FAS-200 comprises up to 18 independent stations with integrated control. This modular equipment features a higher number of stations in the same space, which means that more users will be able to work at the same time.

Top Key Features

- Flexible and compact

- Includes industrial automation technologies

- 18 independent stations

- 24 different assemblies

- More stations for more users

Overview

FAS-200 is a flexible and compact assembly system which includes industrial automation technologies.

FAS-200 comprises up to 18 independent stations with integrated control. This modular equipment features a higher number of stations in the same space, which means that more users will be able to work at the same time.

In addition, it enables making a staggered investment, i.e. starting with an initial basic configuration which can be easily enhanced by adding workstations.

FAS-200 offers professional skills training to suit the world of industry using standardised industrial components.

The different process stations assemble a turning mechanism. To provide the system with greater flexibility, the stations adapt to a wide variety of assemblies, introducing variations in the materials, colours and part sizes. The combination of all these options means that a total of 24 different assemblies can be produced enabling the use of production management strategies.

Key Features

- Flexible and compact

- Includes industrial automation technologies

- 18 independent stations

- 24 different assemblies

- More stations for more users

- Designed & built with industry relevant components

Dimensions

| Dimensions: | FAS-201: 450 x 600 x 1310 mm FAS-202: 450 x 600 x 1500 mm FAS-203: 450 x 600 x 1320 mm FAS-204: 450 x 600 x 1410 mm FAS-205: 450 x 600 x 1370 mm FAS-206: 450 x 600 x 1210 mm FAS-207: 450 x 600 x 1800 mm FAS-208: 450 x 600 x 1310 mm FAS-209: 450 x 600 x 1400 mm FAS-210: 450 x 600 x 1310 mm FAS-211: 450 x 600 x 1910 mm FAS-212: 450 x 600 x 1550 mm FAS-213: 450 x 760 x 1700 mm FAS-214: 450 x 600 x 1200 mm FAS-215: 450 x 600 x 1500 mm FAS-216: 450 x 600 x 1800 mm FAS-217: 900 x 410 x 1310 mm FAS-218: 1800 x 320 x 940 mm |

|---|

Technical Specifications

| FAS-201 450 x 600 x 1310mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Base feeder Position verification Movement to the point of transfer | Auto switch, Reed type (x4) Inductive (x1) | Digital 9/5 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Three-colour indication light (x1) Breakdown simulation system (x1) | Pneumatic linear (x3) | ||

| FAS-202 450 x 600 x 1500mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Incorrect base handling device Insertion of the base in the pallet | Auto switch, Reed type (x4) Vacuum pressure switch(x1) | Digital 9/7 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4) - Vacuum ejector(x1) Breakdown simulation system (x1) | Pneumatic linear (x3) | ||

| FAS-203 450 x 600 x 1320mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Bearing feeder Transfer to the measuring station | Auto switch, Reed type (x4) Microswitch (x1) | Digital 9/7 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Three-colour indication light (x1) Breakdown simulation system (x1) | Pneumatic linear (x1) Pneumatic gripper (x1) Pneumatic rotary actuator (x1) | ||

| FAS-204 450 x 600 x 1410mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Height measurement Bearing insertion | Auto switch, Reed type (x6) Linear potentiometer (x1) | Digital 10/9 Analog 1/0 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) | Pneumatic linear (x4) Pneumatic gripper (x1) Pneumatic rotolinear (x1) | ||

| FAS-205 450 x 600 x 1370mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Pulling out set Bearing pressing | Auto switch, Reed type (x6) Security magnetic (x1) | Digital 10/5 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Safety relay (x1) Hydraulic equipment (x1) Frequency converter (x1) | Pneumatic linear (x2) Hydraulic linear (x1) | ||

| FMS-206 900 x 580 x 1930mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Insertion/extraction of the product in process Feeding the hydraulic press | Auto switch, Reed type (x5) Vacuum pressure switch(x1) | Digital 10/6 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad (x4) - Vacuum ejector(x1) Breakdown simulation system (x1) | Pneumatic rotary actuator (x1) Pneumatic linear (x1) | ||

| FAS-207 450 x 600 x 1800mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Indexing plate Shaft feeder Shaft height measurement Detection of materia | Auto switch, Reed type (x2) Inductive (x1) Capacitive (x1) | Digital 8/6 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Three-colour indication light (x1) Breakdown simulation system (x1) | Pneumatic linear (x7) | ||

| FAS-208 450 x 600 x 1310mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Incorrect shaft rejection Shaft insertion | Auto switch, Reed type (x8) Vacuum pressure switch(x2) | Digital 14/10 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad (x2) - Vacuum ejector(x2) Breakdown simulation system (x1) | Pneumatic rotolinear (x1) Pneumatic linear (x2) | ||

| FAS-209 450 x 600 x 1400mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Indexing plate Lid feeder Detection of material Lid height measurement | Auto switch, Reed type (x1) Inductive (x1) Photoelectric (x2) Linear encoder (x1) | Digital 10/7 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Three-colour indication light (x1) Pressure regulator (x1) | Pneumatic linear (x3) Pneumatic gripper (x2) | ||

| FAS-210 450 x 600 x 1310mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Incorrect lid removal Lid insertion | Auto switch, Reed type (x7) Vacuum pressure switch(x1) | Digital 12/10 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Vacuum pad(x3) -Vacuum ejector(x1) | Pneumatic linear (x2) Pneumatic rotolinear (x1) Pneumatic gripper (x1) | ||

| FAS-211 450 x 600 x 1910mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Screw feeder Transfer handling device | Auto switch, Reed type (x2) Fibre optic photocell (x1) | Digital 7/5 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Vacuum pad(x3) -Vacuum ejector(x1) | Pneumatic linear (x3) | ||

| FAS-212 450 x 600 x 1550mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Screw insertion handling device | Auto switch, Reed type (x4) Solid state auto switch (x2) | Digital 10/6 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) | Pneumatic linear (x2) Pneumatic gripper (x1) | ||

| FAS-213 450 x 760 x 1700mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Robot tool Robot arm and controlling components | Digital 7/7 | ||

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Robot controlling unit (x1) Robot programming console (x1) | Electric screwing tool (x1) 6 axis robot (x1) | ||

| FAS-214 450 x 600 x 1200mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Insertion/extraction handling device Rotary table Artificial vision industrial system | Auto switch, Reed type (x3) Vacuum pressure switch(x1) Artificial vision camera (x1) | Digital 11/14 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Servocontroller (x1) Vision processing unit (x1) Breakdown simulation system (x1) Vision system programming software and cable (x1) | Pneumatic rotary actuator (x1) Electric turntable (x1) | ||

| FAS-215 450 x 600 x 1500mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Faulty product removal | Auto switch, Reed type (x4) Vacuum pressure switch(x1) | Digital 9/6 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Breakdown simulation system (x1) | Pneumatic linear (x2) | ||

| FAS-216 450 x 600 x 1800mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Vertical axis Positioning axes | Auto switch, Reed type (x4) Digital vacuum pressure switch (x1) | Digital 12/12 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Servocontroller (x1) Driver programming software and cable (x1) | Pneumatic linear (x2) Servo-controlled linear actuators (x1) | ||

| FAS-220 900 x 410 x 1310mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Pallet transfer | Auto switch, Reed type (x4) Vacuum pressure switch(x1) | Digital 9/6 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Breakdown simulation system (x1) | Pneumatic linear (x2) | ||

| FAS-230 1800 x 320 x 940mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Transfer | Inductive (x6) Microswitch (x2) | Digital 8/2 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Pneumatic linear (x2) DC motor (x1) | |||

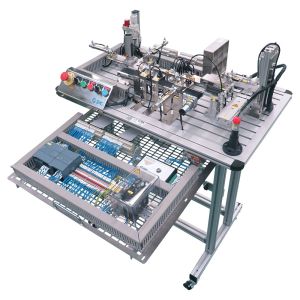

Common elements in all stations:

Power supply, anodised aluminium structure, control keypad, solenoid valve block, labels for cables, electric connection terminals,speed controllers, air treatment unit, control PLC* and manual user manual and practice manual.

FAS-201: Base feeding / verification station

This stations feeds the base for the rotation mechanism and verifies that its orientation / position is correct

FAS-202: Base rejection / transfer station

The second station positions the correctly placed bases on the pallet and rejects those which are incorrect

FAS-203: Bearing feeding / transfer station

This station supplies the bearing and moves it to the measuring position. Bearings can be inserted with two different heights

FAS-204: Bearing measuring / transfer station

The FAS-204 station measures the height of the bearing provided by the previous station

FAS-205: Hydraulic pressing station

This station emulates the pressing of the bearing against the base

FAS-206: Transfer station to the hydraulic press

The FAS-206 station feeds work-piece to the press and picks it up / drops it onto the pallet

FAS-207: Shaft classification station

This station feeds the assembly shafts and verifies their material and position. Two types of shafts exist with different materials

FAS-208: Shaft rejection / transfer station

The eighth station rejects the with incorrect material or faulty positioning and inserts the correct ones into the work-piece

FAS-209: Lid classification station

This station feeds and inspects that are to be added to the work-piece. There are 6 different types of lids with varying material, colour and height

FAS-210: Lid rejection / transfer station

The tenth station rejects incorrect lids or inserts them onto the pallet if they are of the required type for the work-piece

FAS-211: Screw dispensing station

FAS-211 feeds and transfers the screws to the following station

FAS-212: Screw insertion station

The FAS-212 station inserts the four screws into the base

FAS-213: Robotised screwing station

This station integrates robotics technology. The robot screws in the four screws inserted in the product by the previous station

FAS-214: Transfer and visual inspection station

This station performs the quality control for work-piece using an artificial vision system

FAS-215: Rejection station after visual inspection

This station rejects the work-piece if the inspection result is unsatisfactory.

FAS-216: Storage station

The product is removed from the production line and stored using electric actuators

FAS-220: Pallet transfer station

This stations transfers the pallet from one transfer line to another in a parallel transfer configuration

FAS-230: Linear transfer for 4 stations

The FAS-230 station transports the pallet between the stations. Each transfer connects 4 stations

There are currently no files available for download