Specifications are subject to change without prior notice.

MAP-200 - Handling systems

The MAP-200 series consists of seven independent and different training systems.

Top Key Features

- Modular training system

- Improves skills in mechanical handling techniques

- Open environment to develop exercises around

- Emulates a real industrial assembly process

- 7 independent stations

- Designed & built with industry relevant components

Overview

The MAP-200 series consists of seven independent and different training systems.

Each of these carries out a simple assembly process by reproducing subsets of more complex processes found in industry. They can all incorporate the TROUB-200 troubleshooting simulation system.

These four pieces of equipment are offered in three different versions to meet each client’s different requirements:

- Without PLC: It comes assembled, adjusted and wired up. The PLC is not included.

- With PLC: It is supplied fully assembled, programmed and tested. We have a wide variety of PLC brands.

- Assembly kit: The equipment is supplied as a complete kit with of parts. In addition to the practical activities normally available, the student can carry out assembly and equipment adjustment as well as pneumatic and electrical wiring. The assembly instructions and drawings provided in the documentation guide the student through the building and wiring tasks. This version does not include the PLC and power supply

Key Features

- Modular training system

- Improves skills in mechanical handling techniques

- Open environment to develop exercises around

- Emulates a real industrial assembly process

- 7 independent stations

- Designed & built with industry relevant components

Dimensions

| Dimensions: | Map-201: 770 x 580 x 445 mm Map-202: 740 x 400 x 445 mm Map-203: 740 x 400 x 345 mm Map-204: 740 x 400 x 285 mm Map-205: 1200 x 762 x 445 mm Map-206: 750 x 590 x 400 mm Map-207: 500 x 400 x 400 mm |

|---|

Technical Specifications

| MAP-201 770 x 580 x 445mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part feeder Position verification Displacement Rejecting incorrect parts | Auto-switch, Reed type (x4) | Digital 7/4 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Air treatment unit (x1) Speed controllers (x6) Power supply source (x1)* Control PLC ** | Pneumatic linear (x4) | ||

| MAP-202 740 x 400 x 445mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part diversion | Auto-switch,Reed type(x4) Vacuum pressure switch (X1) | Digital 8/4 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Air treatment unit (x1) Speed controllers (x4) Vacuum pad(x3)-Vacuum ejector(x1) Power supply source (x1)* Control PLC ** | Pneumatic linear (x2) | ||

| MAP-203 740 x 400 x 345mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part diversion | Auto-switch, Reed type (x3) | Digital 6/3 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Air treatment unit (x1) Speed controllers (x2) Power supply source (x1)* Control PLC ** | Pneumatic rotary actuator (x1) Pneumatic gripper (x1) | ||

| MAP-204 740 x 400 x 285mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part diversion | Auto-switch,Reed type(x4) Solid state (x2) | Digital 9/3 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Air treatment unit (x1) Speed controllers (x4) Power supply source (x1)* Control PLC ** | Pneumatic rotolinear actuator (x1) Pneumatic gripper (x1) | ||

| MAP-205 1200 x 762 x 445mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Base feeder Position verification Displacement Rejecting an inverted base Bearing assembly Insertion shaft in the assembly Positioning of the lid | Auto-switch, Reed type (x15) Inductive detector (x1) Barrier type photocell (x2) Vacuum pressure switch(X1) Solid state (x2) | Digital 24/15 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation box (x1) Air treatment unit (x1) Speed controllers (x17) Power supply source (x1) Control PLC ** | Pneumatic linear (x6) Pneumatic rotary actuator (x1) Pneumatic roto-linear actuator (x1) Pneumatic gripper (x2) | ||

| MAP-206 750 x 590 x 400mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Positioning axis Warehouse | Auto-switch, Reed type (x2) Encoder (x2) | Digital 10/15 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Touch HMI with built-in PLC (x1) HMI programming software (x1) HMI visualisation software from PC(x1) CC regulator (x1) Servo-driver (x2) Power supply source (x1) | 24VDC electrical linear (x1) Servo-motor electrical linear (x2) Electromagnet (x1) | ||

| MAP-207 500 x 400 x 400mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Feeding and detecting the parts Rejection manipulator Displacement manipulator Stopper | Auto-switch, Reed type (x7) Magnetic adjustment (x1) Vacuum pressure switch (X1) Inductive detector (x1) | Digital 13/10 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Air treatment unit (x1) Speed controllers (x9) Vacuum pad(x1)-Vacuum ejector(x1) Power supply source (x1) Three-colour indication light (x1) Magnetic adjustment amplifier (x1) | Pneumatic linear (x4) Pneumatic gripper (x1) | ||

* Not included in kit version.

** Options: Without PLC, Siemens, Omron, Mitsubishi, Allen Bradley, Schneider. Not included in kit version.

Relevant Technologies

- Electrical panel

- Pneumatics

- Vacuum

- Electric motors

- Sensors

- Programmable controllers

- Manipulators

- Motion control

- SCADA / HMI

- Automated systems

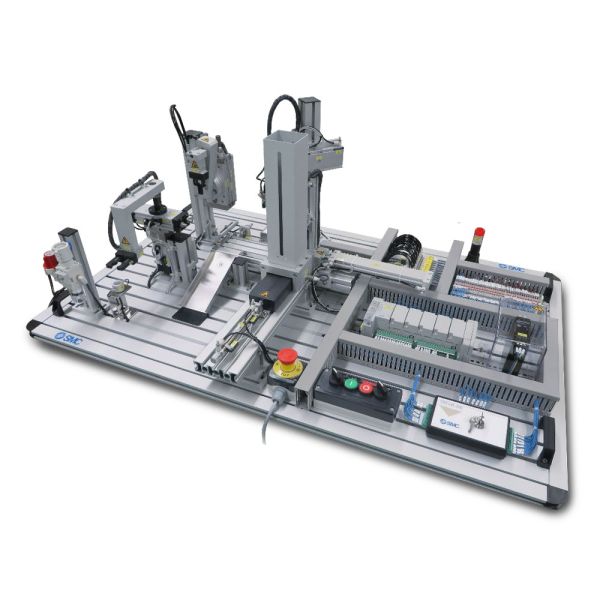

MAP-201 - Part feeder with detector and ejector for incorrect parts

Gravity feeds parts which are checked for orientation. If the part is incorrectly positioned, it is rejected

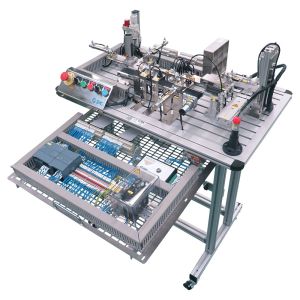

MAP-202 - Vacuum-held handling device with two shafts

Performs a Pick & Place movement of a part using vacuum grippers

MAP-203 - Vertical revolving handling device with internal gripper

Moves a part from one position to another using a rotating manipulator fitted with an inside gripper

MAS-204: Insertion of the shaft

Transfers a part from one position to another using a roto-linear manipulator fitted with an external gripper

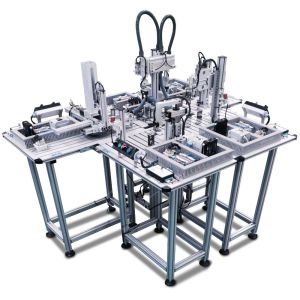

MAS-205: Transfer of the parts

Integrates the four systems: MAP-201, MAP-202, MAP-203, MAP-204, forming an assembly minicell. It carries out the complete assemblydisassembly process in four parts. The troubleshooting simulation system TROUB-200 is included, which generates up to 16 different breakdowns to be diagnosed by the user

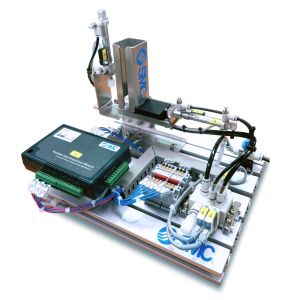

MAP-206 Handling device using electric actuators

It can perform different handling operations on metal parts using a system of 3 electrical Cartesian axes, two of them servo-controlled

MAP-207 - Handling device for parts classification

It performs an automated process of classification and rejection of components made of various materials and sizes

Common elements for all equipment:

anodised aluminium structure, control keypad, electric connection terminals, labels for cables, solenoid valve blocks, user manual and practice manual.

There are currently no files available for download

MAP-200

Handling System

The MAP-200 series consists of 7 different systems to develop skills in mechanical handling techniques.